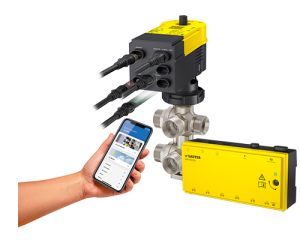

Smart Actuator

3 in 1: Valve actuator, controller and cloud integration for autonomous control of heating and air-conditioning applications

How you benefit from the Smart Actuator

Digitalisation

SAUTER drew on its knowledge of the requirements of digital design when developing the new Smart Actuator. Even in the planning phase, it is easy to check which applications are available as standard or can be downloaded from the cloud. Wireless technology removes the need for complicated network wiring.

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

The field devices required for the application can be connected directly to the actuator or the I/O box. Compared to a conventional installation with central controllers and valve actuators, this reduces the size and costs of the cabinet panels while simultaneously lowering the fire load through less wiring. All product data can be retrieved at any time via the smartphone app and used for the planning.

Uncompromised performance

SAUTER actuator technology for dampers and valves is characterised by its long service life, flexible fields of use and fast fitting. Now expanded to include IoT technology, app operation and integrated controllers for heating and air conditioning applications, the Smart Actuator is ready as the core element for the intelligent buildings of the future.

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

Applications

The Smart Actuator enables autonomous control in heating, ventilation and air-conditioning. SAUTER provides application programs in the cloud for controlling heating and cooling registers in ventilation systems as well as heated and chilled ceilings. When setting up individual plants, planners and installers thus have a wide range of applications to choose from.

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

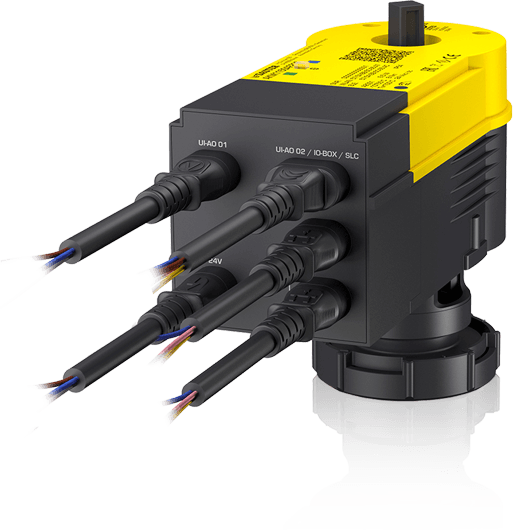

All applications provided have been developed and validated by a SAUTER team of experts. The field devices required for the application can be connected directly to the actuator via two universal I/Os. The optional I/O box allows the range of applications to be extended comprehensively.

Installation and commissioning

The IoT-capable SAUTER Smart Actuator is the intelligent solution for distributing energy in smart buildings and can be commissioned very easily. The connector system in combination with pre-assembled cables ensures particularly fast and error-free installation. The mechanical and colour coding prevents wiring errors.

Installers are supported by the smartphone app. All functions are accessed intuitively:

- Identification

- Selection of the application

- Definition of setting parameters

- Integration into the BA network or the cloud

Operating data can be graphically visualised via the SAUTER cloud. Thus, plant optimisations are carried out online via the MobileApp.

Future-proof communication

The SAUTER Smart Actuator is conveniently integrated directly into the cloud via WLAN. In particular, operators of facilities such as schools or medium-sized office buildings can control and monitor the control loops with their smartphone via the SAUTER cloud.

The Smart Actuator has an RJ45 or RS485 interface and a WiFi interface for integration into Building Management System (BMS) networks. If a BMS network is already present, the Smart Actuator can be incorporated via BACnet/IP or MS/TP.

Predictive maintenance

SAUTER Cloud Services range from commissioning to plant monitoring (inspection) and optimisation (adjustments) to predictive maintenance. Central to these services is the continuous digital inspection that includes, for example, valve leakage, pressure surges and wear.

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

This is enabled by the Smart Actuator’s sensors that record information on the state of the actuator and transfer it to the SAUTER cloud. Here the data is analysed by comparing it to reference values. Thus the current state of the plant can be retrieved at any time and maintenance work can be scheduled according to needs.

Products

Find out more!

Product video

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

Companies

Industry sectors

Services

Innovation

Your location

TLC TECHNICAL SERVICE TRADING COMPANY LIMITED

219/8 Duong so 5 Khu pho 3, Binh Hung Hoa Ward Binh Tan District, Ho Chi Minh City, Vietnam. Tel. +84 (0) 90 2540 929 long.nt(at)tl-controls(dot)com http://www.tl-controls.com/ Sauter Building Control International GmbH Hans-Bunte-Strasse 15 DE-79108 Freiburg i. Br. Tel. +49 761 510 54 05 Fax +49 761 510 54 20 ms.sbci(at)de.sauter-bc(dot)com www.sauter-controls.com